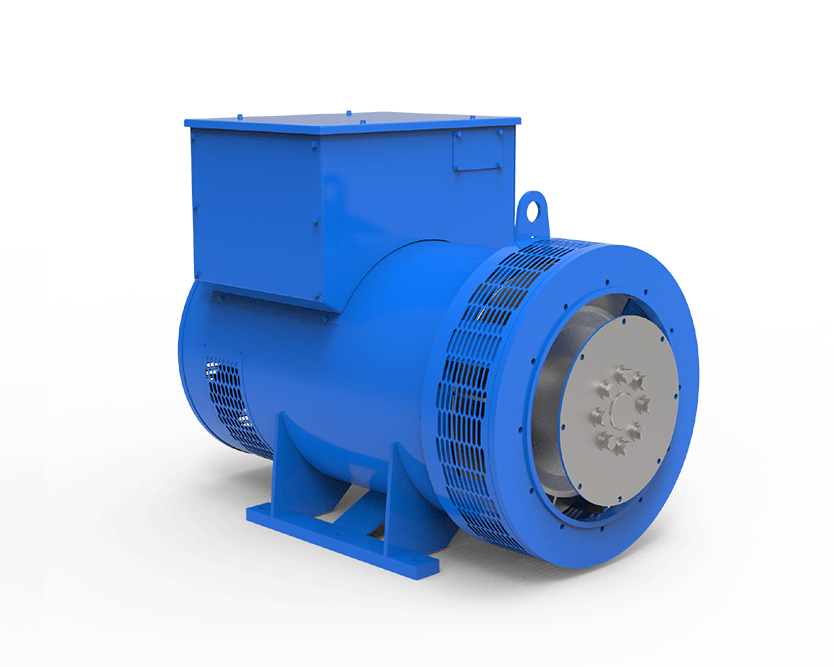

Schwerlastwechselstromgeneratoren sind wichtige Komponenten in vielen kommerziellen und industriellen Anwendungen – hier sind Zuverlässigkeit und Belastbarkeit unter rauen Bedingungen unverhandelbar. Die Schwerlastwechselstromgeneratoren von EvoTec Power sind so konzipiert, dass sie intensiven Betriebsanforderungen standhalten. Dennoch – wie alle Hochleistungsmaschinen – benötigen sie eine angemessene Wartung, um weiterhin auf höchstem Niveau zu funktionieren. Hier erfahren Sie, wie Sie Ihren Schwerlastwechselstromgenerator von EvoTec Power warten können, um sicherzustellen, dass er schwere Aufgaben effektiv und effizient bewältigt.

Regelmäßige Inspektion und Reinigung

Regelmäßige Kontrollen

Regelmäßige Inspektionen sind entscheidend, um potenzielle Probleme frühzeitig zu erkennen, die zu Ausfällen führen könnten. Planen Sie monatliche Kontrollen, um nach Anzeichen von Verschleiß, losen Verbindungen oder Korrosion zu suchen – häufige Probleme in rauen Umgebungen.

Sauberhalten

Staub, Schmutz und Ablagerungen können sich am Wechselstromgenerator ansammeln und so Überhitzung sowie verringerte Effizienz verursachen. Reinigen Sie die Außenseite des Generators regelmäßig mit einem weichen Pinsel oder einem Luftdruckgeber. Stellen Sie sicher, dass die Kühlventilatoren frei von Ablagerungen sind, um eine optimale Temperatur während des Betriebs zu gewährleisten.

Leistungsüberwachung

Diagnosewerkzeuge verwenden

Nutzen Sie Diagnosewerkzeuge, um die Leistung des Wechselstromgenerators kontinuierlich zu überwachen. Prüfen Sie auf konstante Spannungsausgabe und achten Sie auf ungewöhnliche Geräusche, die auf Lagerprobleme oder interne Fehlausrichtungen hinweisen könnten. Sofortige Reaktion auf Abweichungen kann spätere Großreparaturen verhindern.

Antriebsriemen überprüfen

Der Antriebsriemen ist für den ordnungsgemäßen Betrieb Ihres Wechselstromgenerators entscheidend. Untersuchen Sie den Riemen auf Verschleißerscheinungen wie Risse oder Fäden. Ein loser oder beschädigter Riemen kann die Generatorleistung beeinträchtigen und das Risiko von Ausfällen erhöhen. Ersetzen Sie Riemen gemäß den Herstellerempfehlungen – oder früher, falls Verschleiß sichtbar ist.

Elektrische Verbindungen und Komponenten

Sichere Verbindungen

Stellen Sie sicher, dass alle elektrischen Verbindungen fest sind und frei von Korrosion. Lose Verbindungen können zu einer Verringerung der GeneratorEffizienz führen und ein Sicherheitsrisiko darstellen. Wenden Sie zur Korrosionsverhinderung – insbesondere in feuchten oder marinen Umgebungen – Dielektrikumfett an.

Gleichrichter und Spannungsregler überprüfen

Der Gleichrichter wandelt AC in DC um, und der Spannungsregler steuert die Ausgangsspannung. Fehler in diesen Komponenten können zu schlechter Leistung oder Ausfällen führen. Testen Sie diese Komponenten regelmäßig und ersetzen Sie sie, falls Anzeichen von Fehlfunktionen auftreten.

Schmierung und Wartung des Kühlsystems

Lager schmieren

Eine ordnungsgemäße Schmierung reduziert Reibung und Verschleiß in den Generatorlagern. Beachten Sie die Herstellerangaben zu Art und Häufigkeit der Schmierung. Einige Schwerlastwechselstromgeneratoren verfügen über versiegelte Lager, die keine regelmäßige Schmierung benötigen, andere hingegen erfordern eine periodische Pflege.

Kühlsystem warten

Schwerlastwechselstromgeneratoren sind oft mit integrierten Kühlsystemen ausgestattet, um hohe Betriebstemperaturen zu beherrschen. Halten Sie das Kühlsystem sauber und stellen Sie sicher, dass das verwendete Kühlmittel die richtige Menge und Konzentration aufweist. Ersetzen Sie das Kühlmittel gemäß dem Wartungsplan, um Überhitzung und potenzielle Schäden zu verhindern.

Fachgerechte Wartung

Regelmäßige Wartung planen

Selbst mit gründlichen Eigenwartungsroutinen ist fachgerechte Wartung entscheidend, um tiefer liegende mechanische und elektrische Probleme anzugehen. Planen Sie mindestens einmal im Jahr eine fachgerechte Wartung – je nach Nutzung und Betriebsbedingungen kann dies häufiger erforderlich sein. Fachtechniker informieren Sie zudem über aktuelle Wartungsprotokolle und technologische Upgrades, die die Leistung Ihres Generators verbessern können.

Zusammenfassung

Die Wartung Ihres Schwerlastwechselstromgenerators von EvoTec Power ist entscheidend, um sicherzustellen, dass er auch unter anspruchsvollen Bedingungen effizient funktioniert. Regelmäßige Inspektionen, gründliche Reinigung, Leistungskontrolle, Pflege elektrischer Verbindungen, Schmierung bewegter Teile und fachgerechte Wartung bilden die Grundlage einer wirksamen Generatorwartung. Indem Sie diese Richtlinien befolgen, maximieren Sie die Lebensdauer Ihres EvoTec Power-Generators und stellen sicher, dass er zuverlässig Strom liefert, wenn Sie ihn am meisten benötigen. Investieren Sie in routinemäßige Wartung – und sparen Sie sich später teure Reparaturen und Stillstandszeiten.

routine maintenance to save on costly repairs and downtime in the future.